Plywood: The Amazing Artificial Wood You Need to Know

Hey there, folks! Today, we’re diving into the world of plywood – an ordinary-looking yet incredibly versatile and intriguing man-made material. You’ve likely encountered it at furniture stores, construction sites, or during your own home renovations, but do you know its birth story, its diverse varieties, superior properties, wide-ranging applications, and even its eco-friendly side? Well, hold onto your hats because we’re about to unravel the mysteries of plywood in this all-encompassing exploration!

What Exactly Is Plywood?

In plain terms, plywood is an engineered wood product made by stacking multiple thin layers, or veneers, of wood in a specific cross-grain pattern and bonding them together with adhesive. It typically consists of a face layer (outermost), core layers (middle), and a back layer (bottom), each contributing to the panel’s overall stability and visual appeal.

How Plywood Comes to Life

The production of plywood is like a precision “puzzle assembly.” First, logs are sliced into thin veneers, marking the raw material preparation stage. Next, these veneers are coated with glue – not just any glue, mind you, but the critical ingredient holding the plywood together. Common choices include phenolic resin glue and urea-formaldehyde resin. After gluing, the veneers are arranged in a specific sequence, forming a “wooden sandwich,” a process known as lay-up. They undergo pre-pressing to ensure even glue distribution before being subjected to high heat and pressure in a hydraulic press – voila! Out comes the familiar plywood we all know.

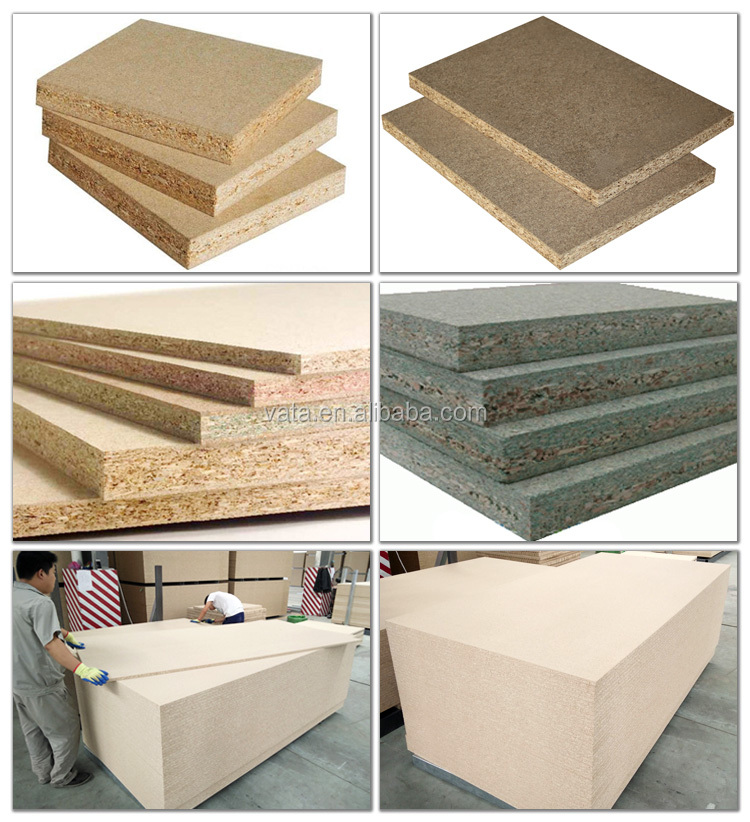

The Plywood Family Tree: A Diverse Array

The plywood family is extensive, with each member sporting unique features. Regular plywood is the baseline model, suitable for a variety of general purposes. Decorative plywood, on the other hand, dresses to impress, like faced plywood adorned with an attractive surface material, while fire-resistant and moisture-resistant plywoods offer special protection for specific environments. Then there are specialty plywoods, such as those used in aerospace and marine applications, designed to withstand extreme conditions with exceptional strength and corrosion resistance – the hardcore players of high-tech domains.

Raw Materials & Glue: The Key to Quality

The choice of raw materials and glue is crucial to plywood’s overall quality. Wood species abound, with pine, poplar, and birch among many options, each with their pros and cons. For instance, pine is lightweight and flexible, while poplar sports attractive grain patterns and excellent workability. Matching the right wood combination enhances the plywood’s overall performance. As for glue, it impacts not only bond strength but also environmental friendliness. Today’s market offers low-emission and even formaldehyde-free adhesives, ensuring product durability while minimizing potential harm to both the environment and human health.

Plywood’s Multifaceted Talents

Plywood boasts a rich array of performance characteristics, much like a Swiss Army knife with numerous functions. In mechanical properties, it excels in bending strength, static bending modulus, and has a moderate modulus of elasticity, making it perform admirably under pressure and bending. In physical properties, it maintains controlled moisture content, swelling, ensuring dimensional stability and minimizing warping. Additionally, it exhibits good weather resistance, corrosion resistance, and even some sound insulation and thermal insulation capabilities. These outstanding traits are all underpinned by stringent technical specifications, such as thickness tolerance, warp, and surface quality – critical benchmarks for determining a plywood panel’s fitness for purpose.

Plywood’s Ubiquitous Presence Across Industries

Plywood’s application scope is vast, spanning virtually every corner of industry. In furniture manufacturing, it’s the go-to material for crafting tables, chairs, cabinets, beds, and more – stylish, functional, and cost-effective. In construction and interior decoration, it graces ceilings, walls, exterior facades, and serves as building templates, both indoors and out. Beyond that, it’s active in packaging materials, vehicle and shipbuilding, musical instrument fabrication – a veritable cross-genre star.

Plywood: Championing Environmental Sustainability

The plywood industry plays a significant role in promoting efficient forest resource utilization and reducing wood waste. By producing plywood, we can create more usable material from fewer logs, demonstrating respect and stewardship for natural resources. Moreover, in response to ever-increasing environmental demands, the industry actively pursues measures like adopting low-emission or formaldehyde-free adhesives, improving manufacturing processes, and embracing forest certifications, all in pursuit of greener, eco-friendlier products.

Looking Ahead: Plywood’s Cosmic Odyssey

With technological advancements and evolving market demands, the plywood industry is marching towards product innovation, intelligent manufacturing processes, and heightened sustainability. Future plywood may become increasingly functionalized and lightweight, catering to more personalized and premium needs. Despite facing challenges from environmental regulations and market competition, plywood, armed with its unique advantages and vast application prospects, is poised to continue shining bright in sectors like building materials and furniture manufacturing, penning new chapters of glory.

Well, dear friends, that concludes our plywood odyssey. We hope this article deepens your understanding of plywood and that next time you encounter it, you’ll view it with an extra dash of appreciation and insight, knowing that beneath this seemingly mundane panel lies a treasure trove of ingeniously designed features and technological innovations. Plywood – it’s worth having in your life!