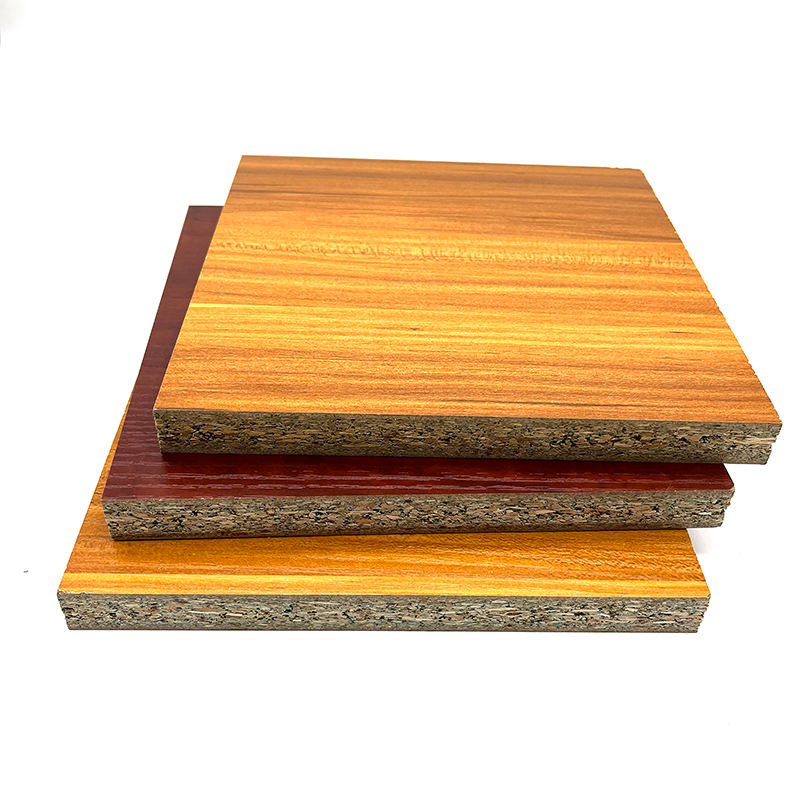

Plywood, a staple in construction, comprises layers of wood veneer bonded together through a process of cross-lamination, employing a hot press. This technique, known as cross-graining, enhances the material’s strength by orienting the grain of each layer perpendicular to its adjacent layer. Typically crafted from an odd number of layers, plywood ensures balance around its center.

Now, let’s talk about Oriented Strand Board (OSB). It’s a type of engineered wood panel akin to plywood but differs significantly in its manufacturing process. OSB incorporates wood strands, ranging from 8 to 15 centimeters in length, mixed with resin and interleaved into thick sheets. These sheets are then bonded together under heat and pressure, forming large, continuous mats of consistent quality with minimal voids or gaps.

When comparing plywood and OSB, aside from their manufacturing methods, several key distinctions should be noted, especially when considering them for roofing projects.

Cost is a significant factor. OSB tends to be notably cheaper than plywood. For instance, a standard 4×8 sheet of plywood may cost around $10, while an equivalent size of OSB could be as low as $6.

Weight is another differentiating factor. Due to its manufacturing process, OSB is generally heavier than plywood. For example, a 23/32-inch 4×8-foot plywood sheet weighs approximately 67 pounds, whereas a similar OSB sheet weighs around 78 pounds. This discrepancy is crucial to consider, particularly for roofing projects, as the added weight of OSB places more stress on roof supports.

Regarding moisture resistance, plywood holds an advantage. Although OSB may take longer to become saturated when exposed to water, it also takes significantly longer to dry. Additionally, OSB swells more when in contact with water, particularly at the edges, due to the release of compaction stress during panel formation. While plywood tends to return to its original thickness as it dries, OSB may remain swollen permanently. Consequently, OSB is more prone to decay from moisture compared to plywood.

In terms of strength, OSB and plywood are similar, but plywood is slightly stiffer, about 10% more than OSB. This subtle difference may result in better nail or screw retention over time in plywood.

Both plywood and OSB emit formaldehyde, but OSB tends to off-gas more. However, proper ventilation can mitigate this risk during construction.

Environmental considerations also come into play. OSB is often considered more environmentally friendly as it utilizes wood chips from smaller diameter trees, allowing for sustainable forestry practices. In contrast, plywood typically requires larger diameter trees harvested from old-growth forests.

OSB holds an advantage over plywood in terms of delamination risk. Plywood, due to its layered structure, may delaminate in humid climates, where the layers begin to separate.

the choice between plywood and OSB depends on various factors. Plywood offers superior moisture resistance and stiffness, while OSB boasts a lower cost and less delamination risk. Both materials are suitable for roof decking when installed correctly and maintained properly.

If you have further inquiries about roof decking or need assistance with your roofing project, feel free to contact us at Colony Roofers. We provide free 30-minute inspections and have a team of knowledgeable professionals ready to address any concerns you may have